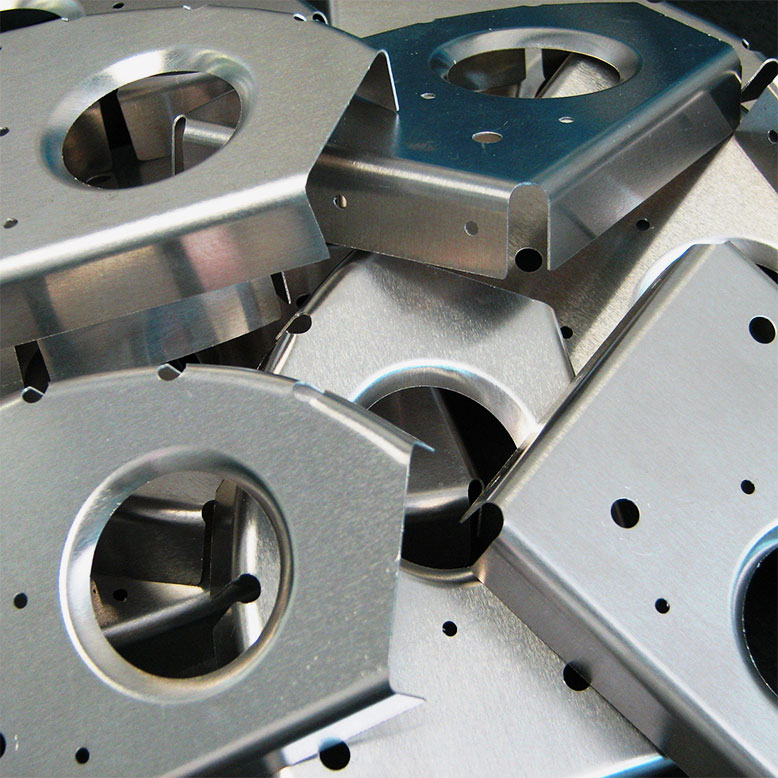

Hydroforming

Hydroforming (or pad-forming) is a cost-efficient method of shaping ductile parts such as aluminum and stainless steel into structurally stiff and strong pieces.

This die forming process uses high pressure hydraulic fluid with a rubber diaphragm that acts as the male mating half to the female die. These female die are inexpensive to make and can form a wide variety of part shapes. Usher’s process is limited to a finish shape depth of 2”. Our 300-ton hydroform press has a large capacity for your hydroforming needs.